|

As natural resources are getting scarcer, it is increasingly important to get the most out of the energy sources we have. Using combined heat and power units is a smart way to optimize the use of energy and get both heat and power from the same generator. In Lollar, Germany, Bosch KWK Systems develops state-of-the-art heat and power units enabling their customer to become more energy-efficient. But as all advanced machinery, Bosch's heat and power units need maintenance every once in a while. With eWON remote routers, Bosch found a way to do this remotely.

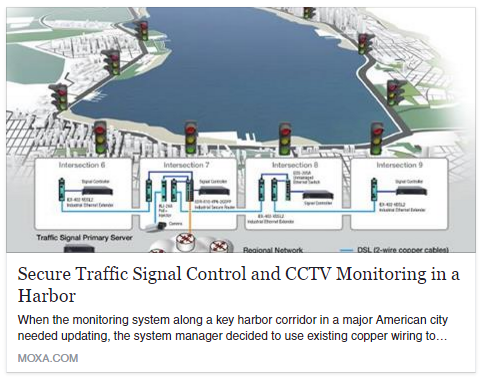

When the monitoring system along a key harbor corridor in a major American city needed updating, the system manager decided to use existing copper wiring to transmit data over significantly longer distances. As this project needed to integrate more systems into one network, serial networks were no longer sufficient to support the expanded network, which is why an industrial Ethernet technology over copper wires via a DSL was required to support more bandwidth over longer distances. In addition, VPN connections and firewall protection were required to ensure network safety and data integrity. Read More

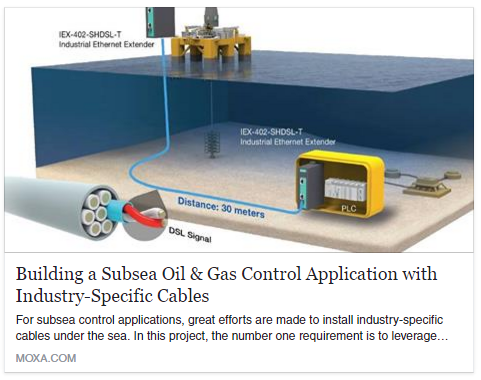

For subsea control applications, great efforts are made to install industry-specific cables under the sea. In this project, the number one requirement is to leverage the existing infrastructure to reduce costs and time spent on installing cables. In addition, oil & gas environments are extremely hazardous due to the high pressures the products are subjected to, so the installation has to be quick and must support remote management and diagnosis. Read More

Micro PLCs from IDEC control 70,000-lb doors at a giant airplane maintenance hangar in San Francisco.A Boeing 747-400 is 232 ft. long, has a wing span of 212 ft. and a tail height of 64 ft.. It weighs close to 875,000 lbs. at takeoff. The Superbay Maintenance Hangar at the San Francisco International Airport can accommodate up to four of these massive airplanes at one time. The hangar has eight doors—four on each opposite sides—allowing access to this huge space measuring 500 x 540 ft, about the size of two football fields.

Each hangar door (Figure 1) consists of two inner and two outer doors, each measuring 130 ft wide and 90 ft high to allow the planes to be towed in and pushed out using tow vehicles. Each door is made of two halves, each 65-ft wide, and weighs 74,000 lb. The door sections are mounted on dedicated rails (much like a train track), and the rails are offset so that adjacent doors can open and close without interfering with their neighboring door. Read More Upgrading automation systems can often extend the life of power generation facilities by decades while reducing downtime, improving operations, and reducing required maintenance. The Maggotty plant in Jamaica offers one such example.

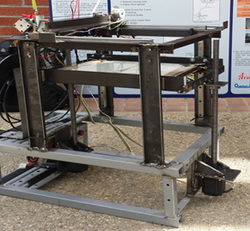

Many power generation facilities have equipment in good running order with many years or even decades of potential service life remaining, but operation is limited by the plant automation systems, which typically have much shorter service lives. Obsolete automation systems fail too frequently and are hard to support, causing excessive downtime. They are also very difficult to tie into other computing systems, which can hinder operational improvements and regulatory compliance. Read more at http://www.powermag.com/digital-control-system-upgrade-gives-hydropower-plant-new-life/?printmode=1 Quantum Automation Supports CAL State Fullerton Students Build an All-In-One Modular 3D Printer5/19/2015

Every year, engineering students from Cal State Fullerton (CSUF) work throughout their academic year in order to create their senior project for faculty and staff to view during their ECS Student Projects Showcase and Awards. Out of all the projects that were being presented, one standout was a group’s design for a functional 3D printer. Read More --->

#SuccessStories

A look at how Moxa’s approach to field-to-control network design facilitates control between sensors at each pipe casting, pump station and HMI.

Read More ---> #SuccessStories

Many of the technologies created for government programs have found their way into industrial applications. Now the sharing of innovation is also moving the other way, as wireless communications and computing power go from the commercial/industrial world into government equipment and facilities.

Read More ---> #SuccessStories

The world’s tallest observation wheel, the 55-story High Roller in Las Vegas, leverages industrial wireless and self-healing fiber-optic networking equipment for position tracking and control. No ordinary Ferris wheel, High Roller is part of a $550 million complex and can carry 40 people per cabin in the 30 minute ride, more than 2200 passengers per hour. Engineering design experts involved included leaders from theme park, bridge-building, gondola, and civil engineering industries. See related technology and services update article with diagrams. Read More --->

#SuccessStories

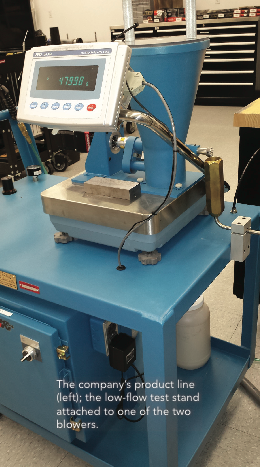

Contact Quantum Automation for more informationFor air filter manufacturer K&N Engineering, a high number of simultaneous parallel processes taxed an older test system. A controls upgrade for the test stations doubled test-process efficiency. K&N Engineering (www.kandn.com) manufactures washable performance air filters and air intake systems for a variety of systems, such as cars, trucks, motorcycles and industrial engines. The goal of this 45-year-old, Riverside, Calif., company is to design and manufacture air filters that provide maximum possible airflow while providing guaranteed engine protection. To do this, K&N Engineering tests all its air filters and intake systems at its laboratory facility, reaching cumulative filtration efficiency between 96 and 99 percent. Read More >

#SuccessStories Quantum Automation Develops Solutions for Sandbag Machines using InduSoft Web Studio

Any company with a complex project like this one needs to choose the right vendors to supply the required hardware and software components. To assist in the selection process, we chose Quantum Automation as our partner because they employ a sophisticated sales support staff that we knew would point us in the right direction. Quantum’s sales engineer Mike Kavanagh was particularly helpful throughout the project, starting with the design phase and assisting through startup and commissioning. Read More --->

#SuccessStories Posted by Quantum Automation on Wednesday, May 27, 2015

Maintaining success is often harder than achieving it. For instance, a microbrewer may come up with an amazing new beer, but it quickly becomes so popular that its high-quality process is stressed by cries for high-volume production. Well, Green Flash Brewing Co. in San Diego, Calif., may have resolved some of this eternal quality vs. quantity tug o' war. Its new plant is controlled by a micro-programmable logical controller (PLC) that gives its meticulous microbrewing process some of the added efficiencies needed to produce more beer and compete with larger operations, while maintaining the quality and taste that made it famous in the first place. Read More --->

#SuccessStories

The Productivity3000 monitors and controls the entire machine via 365 discrete and analog inputs and outputs. Each of the 27 motor drives is interfaced to the controller via a high-speed Ethernet data link.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Orders & Support

714-854-0800 | 7am - 5pm PST

[email protected] | www.QuantumAutomation.com

4400 East La Palma Avenue, Anaheim, CA 92807

714-854-0800 | 7am - 5pm PST

[email protected] | www.QuantumAutomation.com

4400 East La Palma Avenue, Anaheim, CA 92807

|

Copyright © Quantum Automation. All Rights Reserved.

|

Website Development RavingDesignz

|