|

Quantum Automation Develops Solutions for Sandbag Machines using InduSoft Web Studio

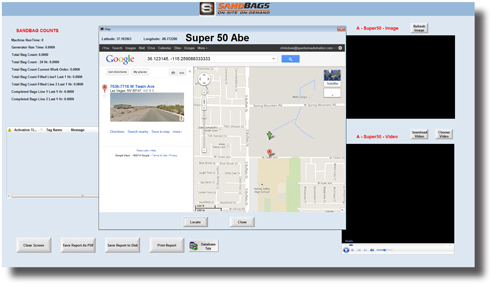

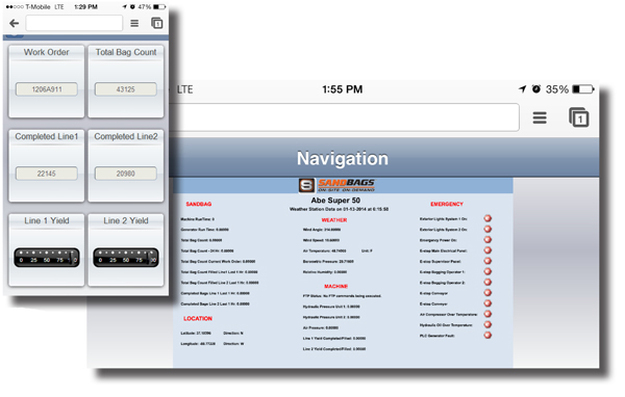

BackgroundDuring natural disaster situations, sandbags are used to protect people and property. In addition to becoming lifesaving tools during floods and storms, sandbags are also used to provide a steady base for oil, gas, and water pipelines. Sandbags are used in these situations because they provide consistent, flexible weight that enables them to become effective barriers and ballast in a variety of applications. One sandbag manufacturer, Sandbags, enlisted the aid of Quantum Automation in creating a system that would improve the monitoring capabilities and control of their existing sandbag machine. For this process, sand gets loaded into a hopper on the Sandbags Super 50 trailer. As the conveyor screw turns, equal amounts of sand get loaded into the measuring cylinders. The sand then drops on the next screw rotation into the sandbags. The sandbags get sewn automatically and dropped onto the conveyor. They then get hand loaded into large totes, which then get loaded onto a flatbed truck to be delivered to the sites that need the sandbags.  Figure 2: The Sandbags Super 50 Machine is a mobile operation that requires connectivity to the central operations station while at the quarry. Figure 2: The Sandbags Super 50 Machine is a mobile operation that requires connectivity to the central operations station while at the quarry. The ChallengeSandbags contracted Quantum Automation to create a full solution for the sandbagging process machine. Initially, the original machine automation was going to be controlled by a C programming language application running under Linux. Fortunately during the early Alpha Development Phase of the machines, it quickly became apparent that the large number of drivers needed to interface communications with the machine’s SCADA system combined with Sandbags MES Network Operations Center requirements located in Las Vegas, NV, was going to require overwhelming application and HMI engineering and development costs, in addition to making Security, Updating, and Ongoing Maintenance of the machines unreasonably expensive and complex in the future. A completely different solution was required. Quantum Automation switched to a faster, more powerful computer for the HMI. The Advantech UNO-2184, running Windows 7 Professional, offered the ability to use native InduSoft Web Studio drivers to integrate the machine processes together. Alarming, Microsoft SQL Server Connectivity for MES and Historization, Emailing, FTP file transfers, Graphics and Design Tools, IP (Intellectual Property) Protection, Embedded ActiveX Controls, OPC, Reporting and PDF Exporting, a usable Symbol Library, Thin Client configuration, Trending, and Troubleshooting were also required design features which are all included in InduSoft Web Studio, and are extremely difficult to program successfully using a C programming language application without a great deal of development time and effort. There were other technical challenges as well. The Sandbags machines, located at various sand quarries within the United States, need to communicate via Cellular Modem, Wi-Fi, or LAN (Local Area Network) back to the Sandbags Network Operations Center. Each location provides video streaming from two on-site Industrial IP cameras. The machines also send local ambient environmental information taken from an on-board AirMar® WeatherStation®, along with machine status and utilization metrics from the PLCs and the Operator Interfaces back to the Sandbags Operations Center. All these design requirements necessitated a solution that can easily communicate with and interface to all these disparate devices. The Solution Figure 3: This screen creates a dashboard for the machine that shows weather information, alarms, location, and the performance of the machine. Figure 3: This screen creates a dashboard for the machine that shows weather information, alarms, location, and the performance of the machine. On each Sandbags Super 50 Machine, there is an Advantech UNO-2184 Industrial Computer running Windows 7 Professional with a Runtime version of Indusoft. Each machine utilizes an eWon EW2620A Secure Cellular Remote Access Router providing VPN (Virtual Private Network) remote access, alarm notification, and software updates. The eWon unit is also utilized for remote troubleshooting of the PLC and Operator Interfaces as well. The eWon unit was essential during the Start-Up period during the Alpha-Development Phase of the machines.Located on the Sandbags Super 50 Sandbag Machine, there is a Moxa® AWK-5232-US Industrial IEEE 802.22a/b/g/n Dual Wireless AP/Bridge/Client. When the device is in the “Wi-Fi Communications Mode”, the InduSoft Web Studio application sends streaming video from both cameras plus the PLC data along with the AirMar WeatherStation data back to the Operations Center. If the sand bagging machine is parked at a site for a longer period of time, main power and Cat6 Ethernet cable can be run directly to the machine instead of utilizing a portable generator and the Cellular or Wifi Modems. The LAN cable now provides real-time data and video to the Sandbags Network Operating Center. Located in the Sandbags Network Operations Center, there is an Advantech HPC-7480 Mission Critical Server running Windows Server 2008, along with a Windows 7 Professional machine, and an InduSoft Web Studio application displaying the operation. An eWon eFive VPN (Virtual Private Network) Appliance is utilized, which has the capability of communicating to 25 individual Sandbag Machines in the field. The VPN appliance can also be upgraded to communicate with 100 remote machines, if needed in the future. The On-Site Video streamed from the machine is used to provide security, operational assurance, and and visual communications in order to assist the Company Operations Manager to make the jobsite more efficient, and record the entire sandbagging process operation, so that there is a continuous video record in the event of an injury or other incident at the jobsite. The AirMar WeatherStation has a GPS (Global Positioning System) to determine where each Sandbags Machine is located for asset management tracking requirements. It also provides wind direction and speed, along with barometric pressure for forecasting precipitation and weather events, in order to determine if they need to stop production because of extreme weather related issues. Each PLC and Operator Interface provides round-the-clock control and status of each machine. The PLCs provides sandbag counts from the two conveyors and compares the count against the maximum theoretical speed in order to determine PE (Process Efficiency). It also provides a Total Bag Count for the day, week, month, job, etc., for billing and MES (Manufacturing Execution System) purposes at the Sandbags Network Operations Center. The PLCs also monitor the status of the Generators for maintenance cycles, and the metrics are used for overall PA (Process Availability) calculations. Historical MES Data and metrics are also stored pertaining to the production of the sandbags and machine operation, such as yield, bags per hour or day, and weather data. Emergency button usage for each machine is also tracked throughout the system. The Integration was completed on the Sandbags Super 50 sandbag machines by Gina Roberts from Dynapac, with special attention given to component (electrical) grounding in order to minimize EMI and RFI (Electromagnetic Interference and Radio Frequency Interference). Protecting the electronic components by placing them into stainless steel enclosures fed with clean, chilled air (since sand is quite abrasive and can quickly damage computers) reduces the internal enclosure temperatures and also helps shield EMI and RFI. Many sand quarries are located in remote or inhospitable (to electronics) areas where the temperature extremes can reach more than 120 degrees Fahrenheit (48.9 degrees Celsius) during the day. The Final Project Start-up was completed by Mark “Gil” Supnet and Chris Doan from Quantum Automation. InduSoft provided engineering assistance in configuring the Web Thin Client and the Mobile Access applications, which is used for the iPad and Android mobile devices utilized on-site and at the Sandbags™ Network Operations Center. The ResultsSandbags is planning to build approximately 5 more of the Super 50s and 5 of their newer Super 44s. Each machine will include an InduSoft Web Studio runtime application on an Advantech UNO-2184s residing on board. Sandbags are used for providing a consistent base to Oil, Gas, & Water pipelines as well as protecting lives and buildings from natural disaster situations. Every year 4 Billion sandbags are made and sewn by hand. The Sandbags Super 50 has the ability to produce 2000 sandbags per hour. FEMA and local agencies have the ability to protect and save more lives and property with the advances made possible by the Sandbags Super 50 machines. The utilization of InduSoft Web Studio in the construction of the Sandbags Super 50 machines saved many months of specialized HMI and SCADA development time over using a C programming language in a Linux environment. This created a much more professional, easier to maintain final product resulting in greater projected operating efficiencies, lowering overall project developmental costs substantially, and providing the project managers with predictable results and the success of the project.

|

|

||||||

Orders & Support

714-854-0800 | 7am - 5pm PST

[email protected] | www.QuantumAutomation.com

4400 East La Palma Avenue, Anaheim, CA 92807

714-854-0800 | 7am - 5pm PST

[email protected] | www.QuantumAutomation.com

4400 East La Palma Avenue, Anaheim, CA 92807

|

Copyright © Quantum Automation. All Rights Reserved.

|

Website Development RavingDesignz

|